Knowledge & Reliability

Description

High-Performance Container Data Center for Mission-Critical Operations

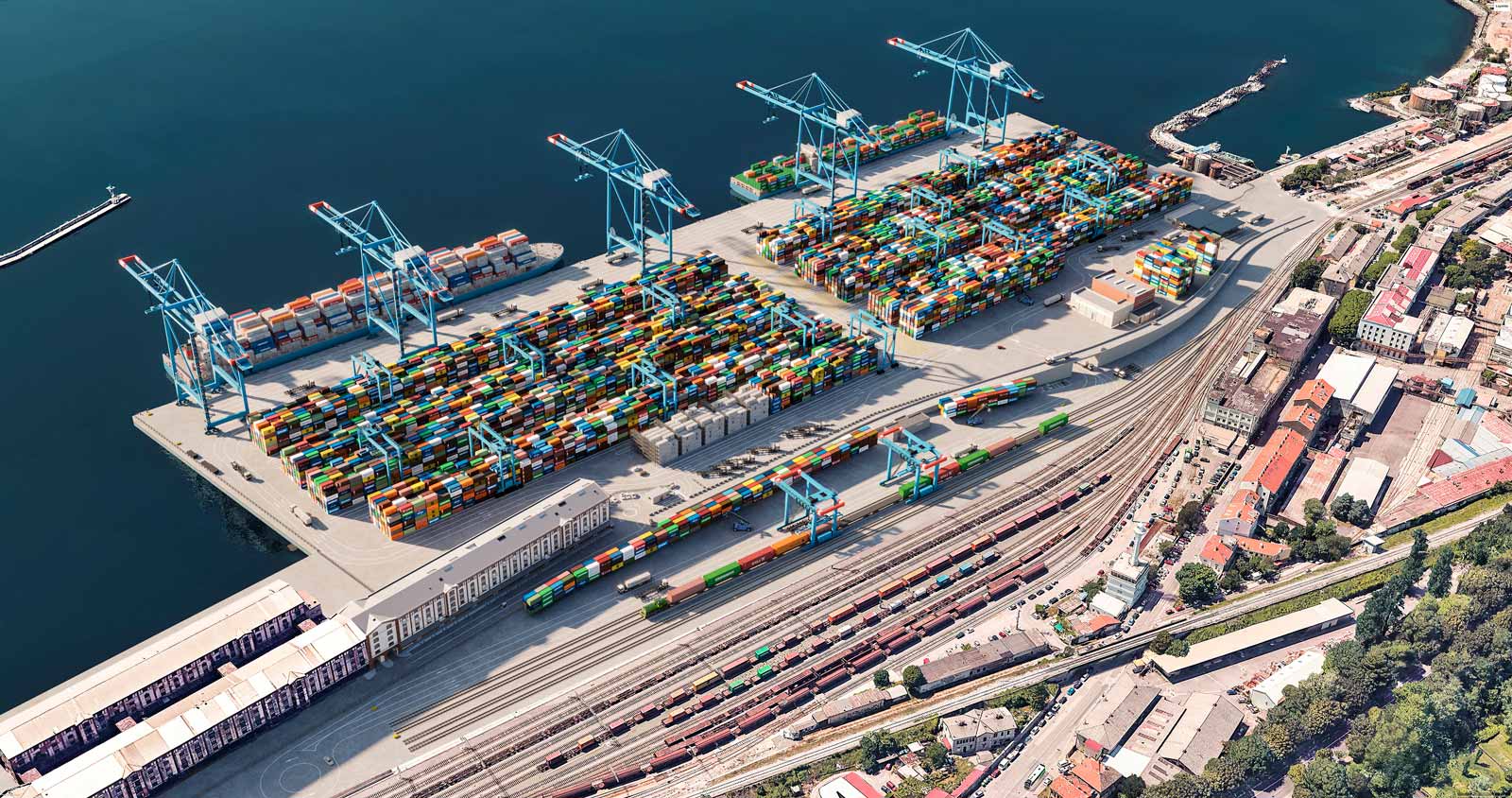

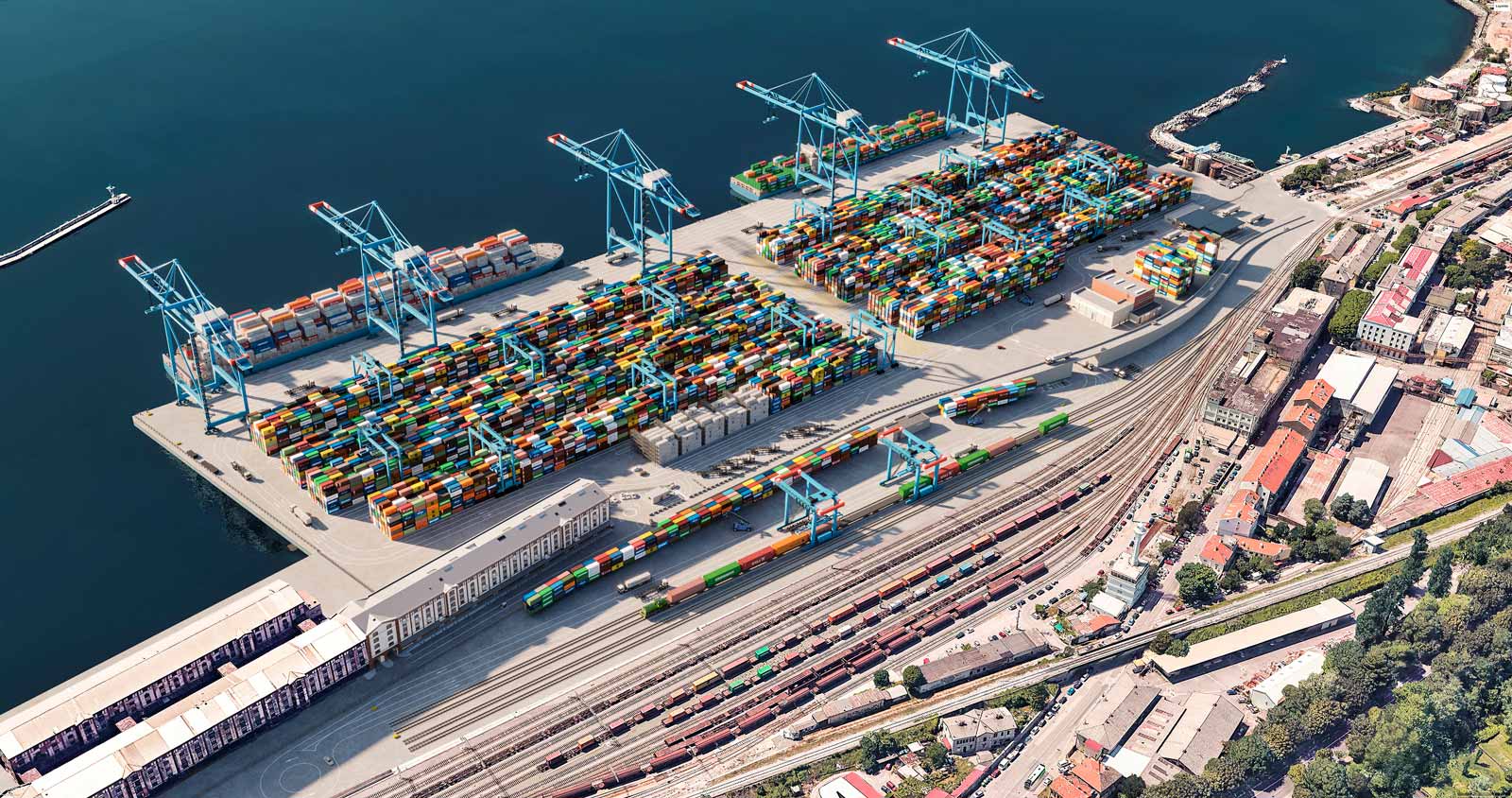

CDC RIJEKA

CLIENT

Rijeka Gateway - APM Terminals and Enna Group

APM Terminals is part of Maersk,a global provider of integrated logistics solutions operating in 130 countries. In Croatia, through its subsidiary Rijeka Gateway, it manages one of the most technologically advanced container terminals in Europe.

OBJECTIVE

A high-reliability data center that meets the highest demands of modern IT environments and enables the safe, efficient, and sustainable operation of the Rijeka Gateway terminal.

CHALLENGES

Spatial Constraints: Achieving high computing density and flexibility in a limited space.

Speed of Implementation Avoiding lengthy and costly construction projects to establish and activate new infrastructure in a very short period.

SOLUTION

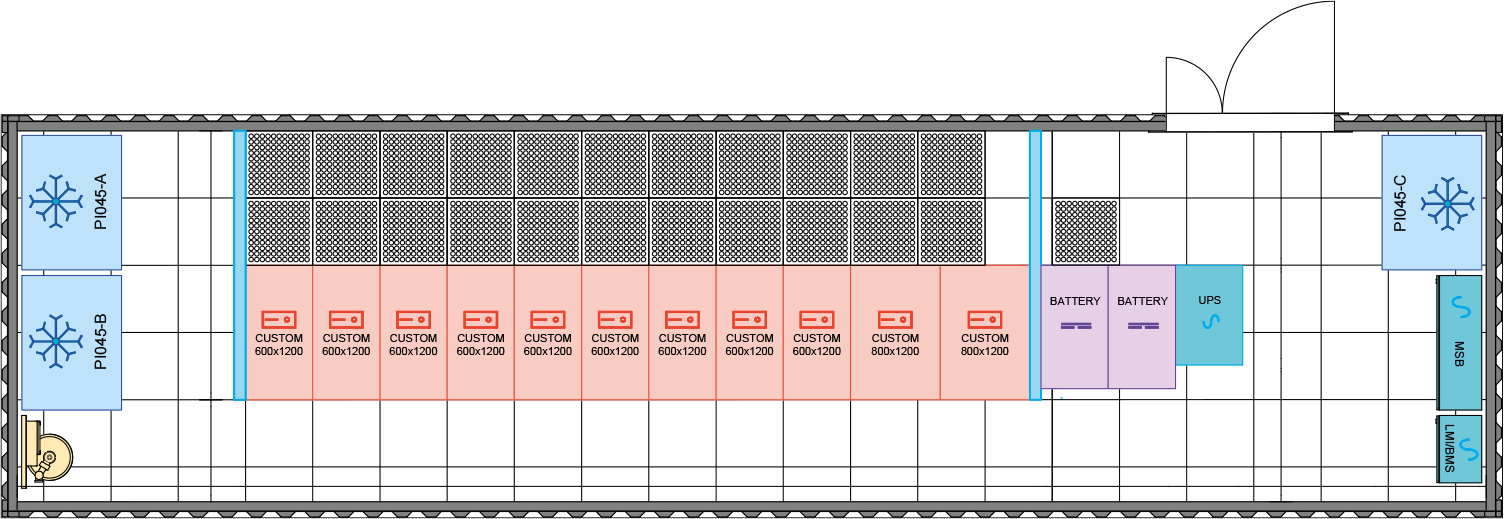

A high-performance container data center that, due to its prefabrication and modularity, allows for rapid and cost-effective implementation while ensuring safety and all the functionalities of a modern data center.

PROJECT BACKGROUND

Rijeka Gateway is the largest project and an investment in the logistics sector in Croatia Worth 380 million euros. The terminal in Rijeka – a joint venture between APM Terminals and ENNA Group – will be the most advanced in the Adriatic region, with most of its equipment electrified and largely remotely operated. Reaching new standards of collaboration excellence, companies openly embrace innovation and sustainability, projecting Croatia and the region forward in time – delivering the port experience of the future, today.

In the first phase, the terminal will feature a 400-meter-long berth, an annual transshipment capacity of 650,000 TEU, and the ability to handle vessels of up to 18,000 TEU. In the second phase, the berth is planned to be extended to 680 meters, increasing the annual transshipment capacity to 1,055,000 TEU and enabling the handling of vessels of up to 24,000 TEU.

Managing terminal’s complex equipment demands a state-of-the-art, robust, reliable, and secure IT environment. In the heart of it are two containerized data centers, designed and executed by NTR inženiring. For the Rijeka Gateway data center, the client required a turnkey solution from a trusted and experienced partner capable of offering state-of-the-art, customized solutions in power supply, energy efficiency, and security, including all necessary supporting infrastructure, such as an automated remote monitoring system, as well as completing the entire project in an exceptionally short timeframe. Initially, the primary data center was planned as a traditional building. However, during the project, it became evident that obtaining permits and preparing documentation for traditional construction would significantly delay the center's operational start. Therefore, we designed a new solution where both the primary and supporting centers were standalone containerized data center units (CDC). This modular, prefabricated plug-and-play concept allows for quick execution and setup while ensuring all the security and functionalities of a modern data center. The client accepted our proposal, and between November 2023 and October 2024, we successfully designed, executed, and launched both the primary and the supporting unit of CDC Rijeka.

»We are impressed with the professionalism, expertise, and exceptional execution speed.

NTR Engineering has fully justified our trust.«

Jean-Louis Sebapo

Technology Project Lead,

APM Terminals

High-Performance Container Data Center for Mission-Critical Operations

(PDF | EN)

Visokozmogljiv kontejnerski podatkovni center za zahtevnejša okolja

(PDF | SL)

PROJECT RESULTS

The advanced CDC Rijeka data center ensures the stable operation of high-performance IT equipment and provides reliable support for managing the most complex systems. It boasts flexibility, exceptional energy efficiency, and security. The center's core is the custom-developed DCIM monitoring system, which enables remote supervision and a comprehensive overview of the entire infrastructure's operation. With CDC Rijeka, we fully met all client requirements and expectations. Our adaptability, excellent cooperation with APM Terminals, and record-breaking execution time further enhanced client satisfaction. This project proves that with our expertise, innovation, and professional approach, we can create top-tier solutions and successfully execute the most demanding projects globally.

| SPECIFICATIONS | KEY FEATURES |

|---|---|

| Module Dimensions: | 13.4 m x 3.6 m x 3.8 m (W x D x H) |

| Number of System Cabinets: | 11 Vertiv MIR2 cabinets, each with two integrated PDU units |

| Total IT Equipment Capacity: | 462 rack units |

| Peak Power per Cabinet: | Up to 11 kW (upgradable to 22 kW) |

| Average Power per Cabinet: | 8.2 kW |

| Total Max IT Equipment Power: | Up to 90 kW (optional up to 110 kW) |

| UPS System: | Modular Vertiv APM2/300, 4 modules of 60 kW, total 180 kW with N+1 redundancy |

| Battery Type: | Li-Ion, 30-minute autonomy at 150 kW |

| Power Distribution: | Separate A and B branches, A with UPS support, B directly from backup power, each branch with Vertiv iMPB busbar system with electrical measurement at each output |

| Backup Power Source: | External 200 kW diesel generator |

| Cooling: | 3 cooling cabinets with DX cooling and humidity regulation (CRAC), Vertiv PDX PI045 with continuous power regulation and HCR076 outdoor unit |

| Cooling Power: | 59 kW per CRAC unit |

| Total Cooling Power: | 118 kW with 2+1 redundancy |

| Fire Protection: | Structural fire protection EI90 |

| Active Fire Safety: | Fire detection with VESDA and fixed fire suppression system using NOVEC 1230 |

| Other Security Systems: | Intrusion Detection System (ISD), access control, video surveillance |

| Monitoring System: | Integrated BMS monitoring system (NTR CDC DCIM) |