Energy-efficient technical cooling systems

Other solutions

Of the total amount of energy consumed by data centers, an average of 45% of electricity is used on technical cooling systems. Hence the greatest savings can be achieved in this area. For this there are some simple recommendations:

- The use of an advanced cooling system that cools using groundwater or free cooling, allows cooling without the operation of compressor units at appropriate low outdoor temperatures.

- Change the operating temperature of the room. In the old center, the temperature is set to 20 to 22 degrees Celsius. But we can turn up the heat to 27 or 28 degrees without harm to the equipment, which means longer operation time without using external compressor units.

- Properly size the cooling system and use devices that are adapted to run in the system space.

The table below shows the typical consumption of electrical energy for different types of technical cooling systems in centers:

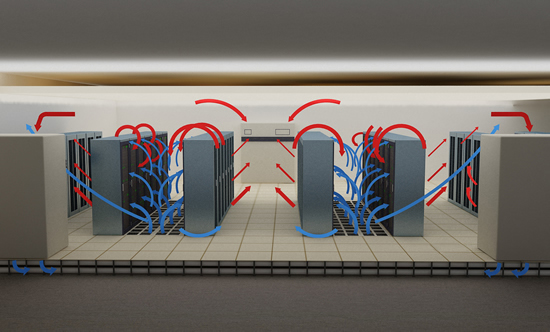

Layout of air flow

A relatively simple measure to reduce energy consumption is the establishment of appropriate working conditions within the system and networking cabinets with the construction of a closed cold area (Cold Aisle Containment). It is a concept where closed cold areas are built above the exhaust of cold air between system types. This prevents the mixing of cold and warm air and provides additional drafts for servers. Obstruction of a cold area is carried out by locking elements around the system and networking cabinets and the closure (closing) of empty areas within the system and networking cabinets. It is necessary to pay attention to the sealing of all the apertures in the raised floor other than the inlets.

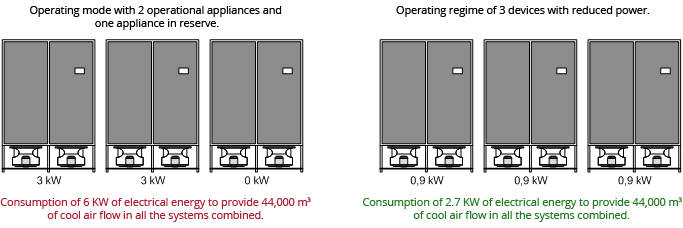

Simple yet effective measure is also the management of redundant cooling equipment. Correctly adjusting the fan speed in cooling cabinets and correct burden-sharing between the cooling systems can save considerable electrical energy. This is especially true for free cooling since free cooling can be provided at significantly higher outdoor temperatures.